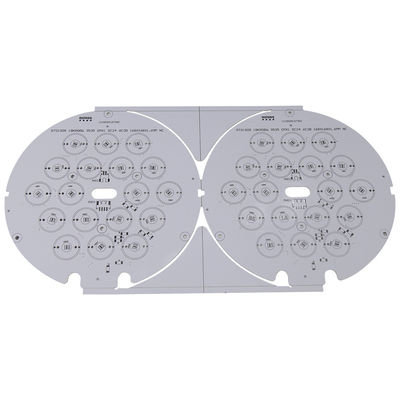

PCB factory custom led mcpcb 94v0 board aluminum pcb led bulb lights

|

|

|

Layers

|

1 Layer

|

|

Material

|

Aluminum

|

|

Application

|

LED

|

|

Copper thickness

|

1oz

|

|

Board thickness

|

1.6mm

|

|

Min. Hole Size

|

4mm

|

|

Min. Line Width

|

39mil

|

|

Min. Line Spacing

|

22mil

|

|

Surface Finish

|

LF_HASL

|

|

S/M Color

|

White

|

|

Legend Color

|

Black

|

|

Special Process

|

HDI, BVH, back drill, pressfit hole, edge plating, VOP, counter sunk, half hole, gold plating, gold finger, ENIG+OSP, flex board, rigid-flex board

|

Aluminum PCB substrate is a new type of heat sink metal plate, which is different from the traditional heat dissipation metal plate. The inherent characteristics of the aluminum substrate can minimize the thermal conductivity, so that more heat can be discharged to the maximum extent Cooling effect. The aluminum substrate is mainly composed of three parts, namely a circuit layer, an insulating layer and a metal layer, and a double panel is used in some high-end aluminum substrate designs. This double panel is hardly used on the traditional radiator metal plate. Because most traditional metal plates use multi-layer boards, the disadvantage of multi-layer PCB boards is that the heat dissipation effect cannot be maximized and cannot meet the user's heat dissipation requirements.

As a new type of thermally conductive metal plate, aluminum substrate has been widely used now. In home computers, car stereos, and our most popular LED lamps, their radiator metal plates are all aluminum substrates. In many fields where the aluminum substrate is used, it must be attributed to its own advantages, so what are the high-quality features of it? It's as following:

The surface of the aluminum PCB substrate uses a special technology-surface mounting. Through this technology, it can maximize the treatment of the heat generated by the product during the heat dissipation process or during the circuit to achieve the best heat dissipation effect .

A major feature of aluminum substrates is that while minimizing the temperature of the product, it can also ensure that the use efficiency of the product will not be reduced, because if it is at the expense of reducing the use efficiency of the product, it will not be worth the loss. In addition, the metal core PCB substrate is to a certain extent. Can prolong the service life of the product.

The volume of the aluminum substrate is small, so its cost price and occupied space are relatively small.

Shenzhen Yizhuo electronics Co.,Ltd is a high-tech enterprise. Since its establishment in 2012,

it has been committed to the innovative development and production of electronic products.

Now it has established a stable R&D team and it has had more than 5,000 square meters of production site.

The products have passed ISO 9001:2015 international quality management system, CE,ROHS, and UL international certification.

FAQ:

Q1. What file formats do you accept for PCB PCBA production?

A. Gerber file: CAM350 RS274X

PCB file: Protel 99SE, P-CAD 2001 PCB

BOM: Excel (PDF,word,txt)

Pick and place file

Q2. Do you have MOQ limited?

A: We don’t have any MOQ limited, the minimum order we accept is 2 pcs.

Q3: How long can I receive the sample?

A: After you make a payment and send us confirmed files,your samples will be ready within 3-5 work days. If there are some urgent orders,we can produce with within 48 hours with an extra express fee.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!